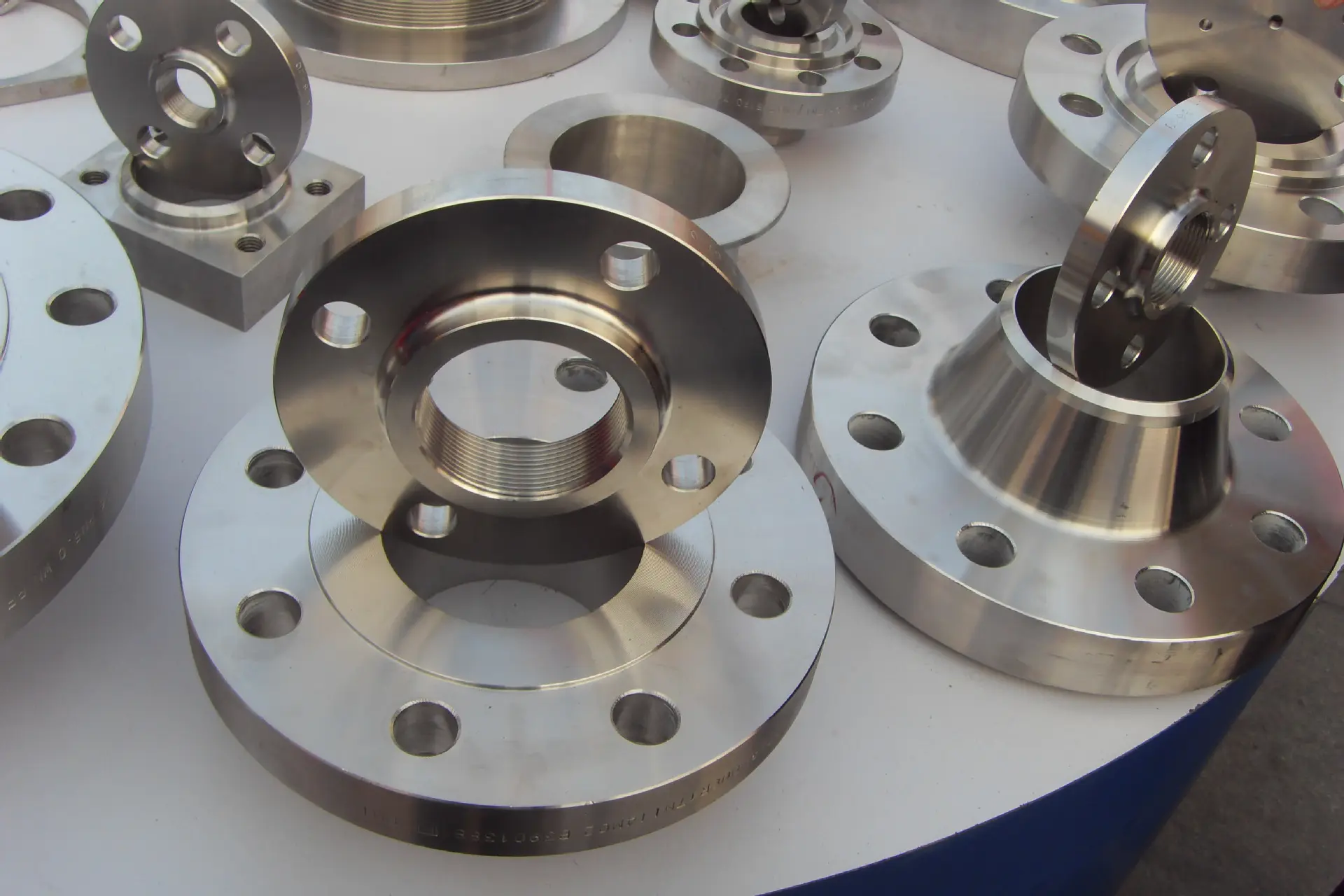

Precision Steel Forging Manufacturer

Steel forging is a kind of metal pressure processing, and the finished product is made by forging the billet. Usually, the metal is heated to a certain temperature, and then repeatedly struck and struck with a hammer to deform it and achieve the desired shape and size.

Steel parts forging process

Due to the strength and hardness of steel, the most widely used forging technique is warm die forging. The process begins by selecting the steel workpiece and making the dies that will help achieve the desired shape of the forging. The steel workpiece is heated to the crystallization temperature at which plasticity is achieved. The heated steel is placed over a die where it is stamped into the desired shape. The forgings then go through a heat treatment stage to achieve the highest possible hardness and strength. Stamping is done by using a hydraulic system to provide the force needed to deform heated steel. However, the heat treatment stage is the most important stage in the forging process. This treatment stage helps to improve the quality of the forging.

Advantages of steel forgings

The greatest benefit of using steel forged components is their mechanical properties. These forgings are harder and stronger, so they are ductile and more resistant to wear. Because of their high hardness and strength, steel forgings can withstand the harshest abrasive conditions. The hardness of these forgings comes from the new, finer grain and retained fibrous structure that the forged steel parts acquire after the forging process. Another advantage of using steel forged components is longer life. These components last longer than comparable components due to lower wear rates. It is also worth mentioning that using steel forged parts is more cost-effective than machined or cast steel parts. These forgings can withstand harsh and harsh conditions, making them last longer.

Industries using forged steel parts

Automotive, industrial machinery and equipment, marine, aerospace and many other industries are rapidly adopting forged steel. The agriculture, defense and construction industries are also increasingly adopting forging technology. However, the automotive industry has been the largest consumer of steel forgings. The automotive and motorcycle industries currently use steel forgings in large quantities. Today, nearly all automotive steel parts are forged. Besides that, most fasteners, mining tools and equipment are also forged from steel. It is also to be noted that the number of steel forging manufacturers in the market has also grown rapidly over the past few years.

The adoption of steel forgings is growing rapidly in industries that use metal parts. The automotive industry is one of the leading industries for this adoption. The adoption of steel forged components will continue to proliferate as steel forging technology advances and more forging manufacturers become available.