Forged Steel Sheave Wheels

Forged steel sheave wheels are an important part used in lifting and conveying systems. They are usually made of steel through a forging process. The main function of the forged steel sheave wheel is to realize the lifting, movement and transmission of goods by connecting the sheave wheel with ropes, wire ropes or chains.

According to the use and structural characteristics, there are several classifications of forged steel sheave wheels:

● Single sheave wheel: It is the most common type of forged steel sheave wheel, which consists of a sheave wheel basket and bearings. Single sheave wheels are usually used in simple lifting and transmission systems, such as manual winches, lifting machinery, etc.

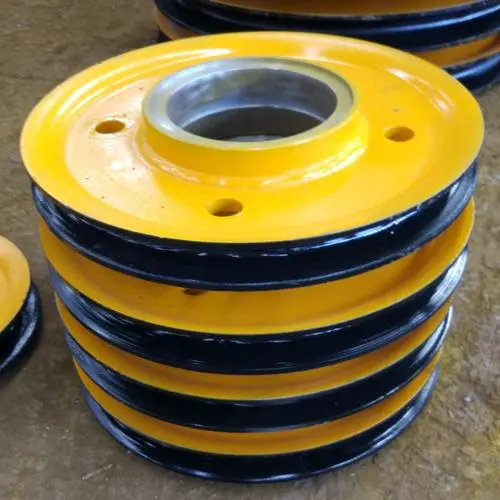

● Multi-sheave wheel: It is a sheave wheel assembly composed of multiple sheave wheels. They can adopt different layouts and structures, such as series, parallel or compound, to provide greater power transmission ratio and smoother transportation. Multi-sheaves are commonly used in heavy lifting equipment and large conveyor systems.

● Eccentric sheave wheel: is a sheave wheel with an eccentric shaft that can change the direction of a rope or chain. It is usually used in situations where the direction of movement needs to be changed, such as elevators, slope conveyors, etc.

● Variable speed sheave wheel: A sheave wheel with an adjustable device that can change the speed of a rope or chain. It is usually used in situations where transportation speed needs to be adjusted, such as lifting machinery, conveyor lines, etc.

● Special sheave wheels: In addition to the above common sheave wheel types, there are also some special-purpose forged steel sheave wheels, such as wire rope sheave wheels, guide sheave wheels, guard sheave wheels, etc. They design and manufacture sheave wheels with special functions and structures based on specific working environments and requirements.

Performance features:

● High strength: Made by forging process, the strength and hardness of steel can be improved through forging. This makes the forged steel sheave wheels have high load-bearing capacity and fatigue resistance, and can withstand heavy loads and long-term use.

● Wear resistance: The surface is usually specially treated, such as heat treatment or surface coating, to improve its wear resistance. This allows the sheave wheel to resist wear and tear over long periods of use, extending the life of the sheave wheel.

● Low friction coefficient: When the sheave wheel comes into contact with ropes, wire ropes or chains, the friction loss is small, which can reduce energy consumption and heat generation.

● Good guiding performance: It can ensure the correct movement trajectory of materials such as ropes or chains on the sheave wheels and avoid deviation and slipping.

● Stability: Able to maintain a stable and reliable working condition during operation, reduce shaking and vibration, and ensure the safety of lifting and transportation.

● Corrosion resistance: Use anti-corrosion coatings or special materials to improve its corrosion resistance. This allows the sheave wheel to be used in wet, corrosive environments for extended periods of time, reducing corrosion and damage.